- 路 Microwave

- 路 Atmospheric Pressure Microwave 路 Pressure Microwave 路 Parallel Microwave

- 路 Ultrasonic 路Low Temperature Ultrasound

- 路 Ultraviolet Light

- 路 Microwave Heating 路 Atmospheric Pressure Synthesis 路 Atmospheric Pressure Catalysis 路 Atmospheric Pressure Extraction

- 路 Sample Preparation 路 Microwave Digestion

- 路 Soil Digestion 路 High Pressure Synthesis

- 路 Solid Phase Synthesis

- 路 Organic Synthesis

- 路 Ionic Liquid Synthesis

- 路 Degradation Of Natural Organic Matter

- 路 Natural Product Extraction / Purification

河北祥鹄科学仪器有限公司

300A Preparation and Properties of BiOBr_Cotton Composites

This paper was completed by a researcher from the School of Chemical Engineering and Pharmaceutical Engineering of Wuhan University of Technology. The paper discusses the preparation and performance of BiOBr/cotton composite materials, and published it in the important journal

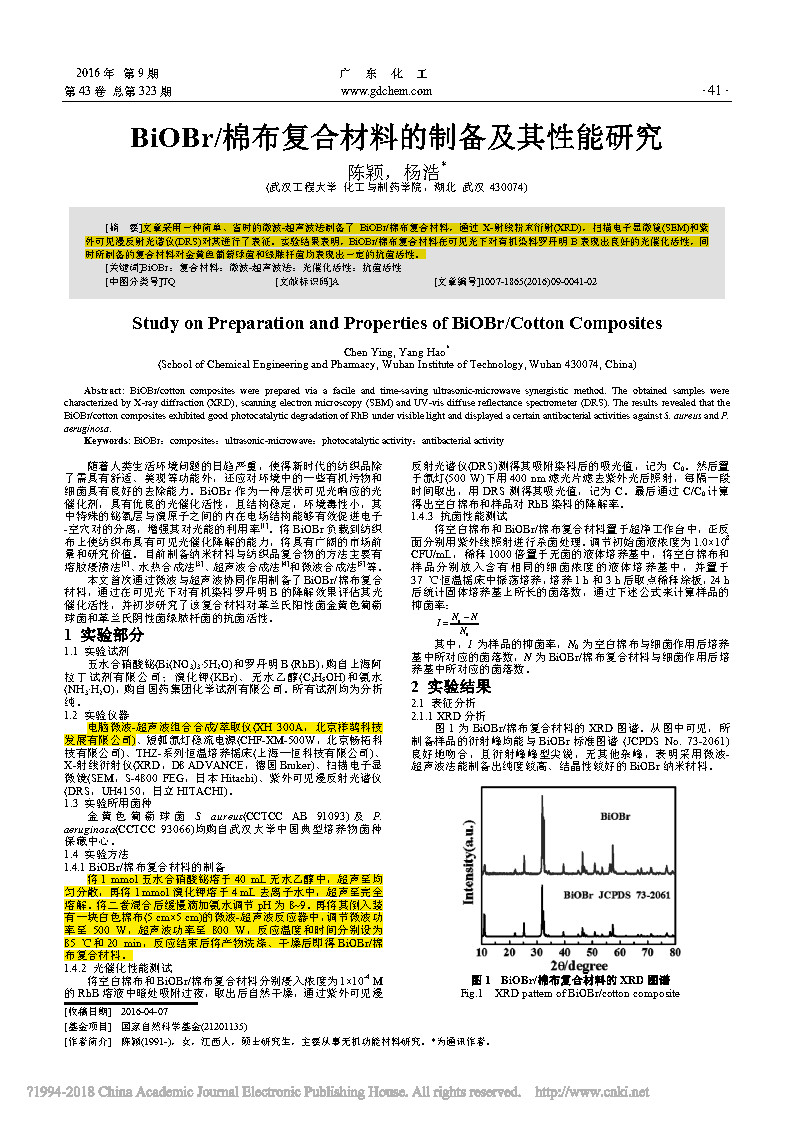

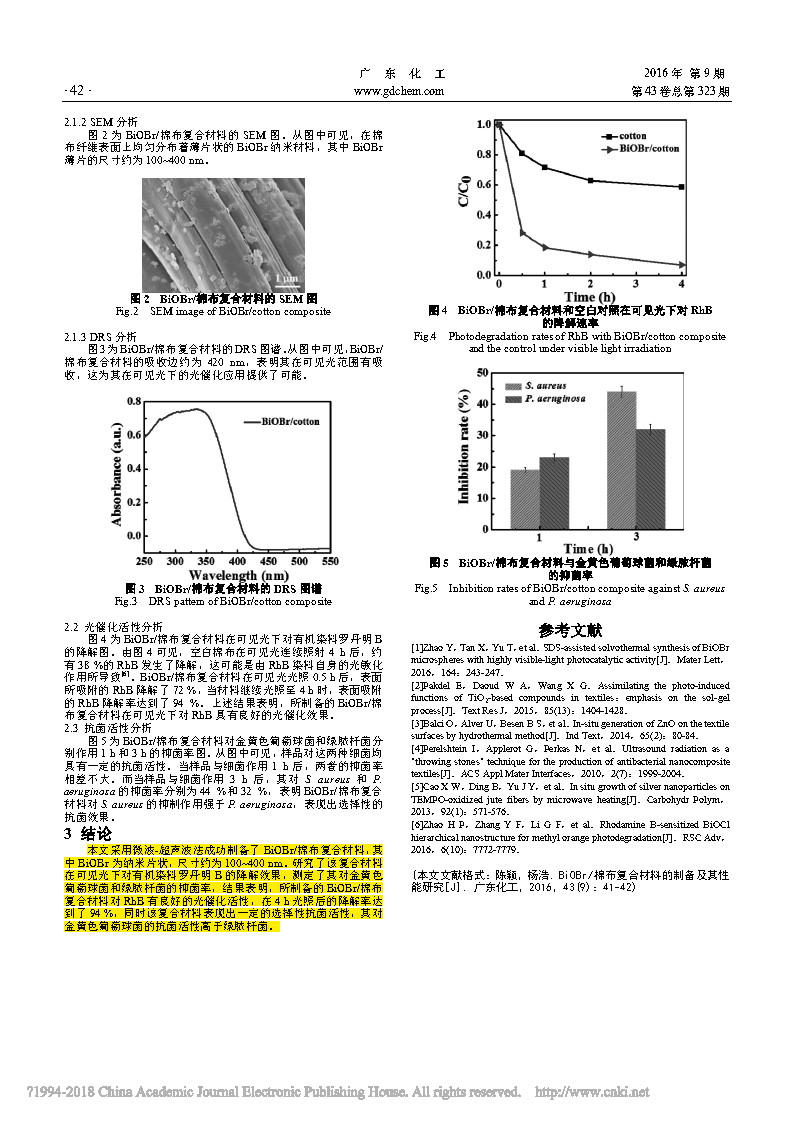

In this paper, a simple and time-saving microwave-ultrasonic method was used to prepare BiOBr/cotton composites, which were processed by X-ray powder diffraction (XRD), scanning electron microscopy (SEM) and UV-visible diffuse reflectance spectroscopy (DRS). Characterization. The experimental results show that the BiOBr/cotton composite exhibits good photocatalytic activity for the organic dye rhodamine B under visible light, and the composites exhibit certain antibacterial activity against Staphylococcus aureus and Pseudomonas aeruginosa.

Fig.1/2↑

Fig.2/2↑

In this paper, BiOBr/cotton composites were successfully prepared by microwave-ultrasonic method, in which BiOBr is nano-sheet and the size is about 100~400 nm. The degradation effect of the composite on the organic dye Rhodamine B under visible light was studied. The inhibition rate of Staphylococcus aureus and Pseudomonas aeruginosa was determined. The results showed that the prepared BiOBr/cotton composite had good effect on RhB. The photocatalytic activity reached 94% after 4 h light, and the composite exhibited certain selective antibacterial activity, and its antibacterial activity against Staphylococcus aureus was higher than that of Pseudomonas aeruginosa.

1 mmol of cerium nitrate pentahydrate was dissolved in 40 mL of absolute ethanol, sonicated to uniform dispersion, and 1 mmol of potassium bromide was dissolved in 4 mL of deionized water and sonicated to complete dissolution. Mix the two and slowly add ammonia to adjust the pH to 8~9. Then pour it into a microwave-ultrasonic reactor equipped with a white cotton cloth (5 cm), adjust the microwave power to 500 W, ultrasonic power to 800 W, and set the reaction temperature and time to 85 ° C and 20 min, respectively. After the product is washed and dried, a BiOBr/cotton composite material is obtained.

京ICP备15050585号

京ICP备15050585号