- 路 Microwave

- 路 Atmospheric Pressure Microwave 路 Pressure Microwave 路 Parallel Microwave

- 路 Ultrasonic 路Low Temperature Ultrasound

- 路 Ultraviolet Light

- 路 Microwave Heating 路 Atmospheric Pressure Synthesis 路 Atmospheric Pressure Catalysis 路 Atmospheric Pressure Extraction

- 路 Sample Preparation 路 Microwave Digestion

- 路 Soil Digestion 路 High Pressure Synthesis

- 路 Solid Phase Synthesis

- 路 Organic Synthesis

- 路 Ionic Liquid Synthesis

- 路 Degradation Of Natural Organic Matter

- 路 Natural Product Extraction / Purification

河北祥鹄科学仪器有限公司

300A Optimization of microwave-assisted extraction of polysaccharides from Brassica chinensis

This research was completed by a researcher from the Key Laboratory of Food Safety and Testing of Guangxi University of Guangxi Guilin University. The paper discusses the optimization of the microwave-assisted extraction process of polysaccharides from the polysaccharides of the genus Corydalis, and published it in the important journal

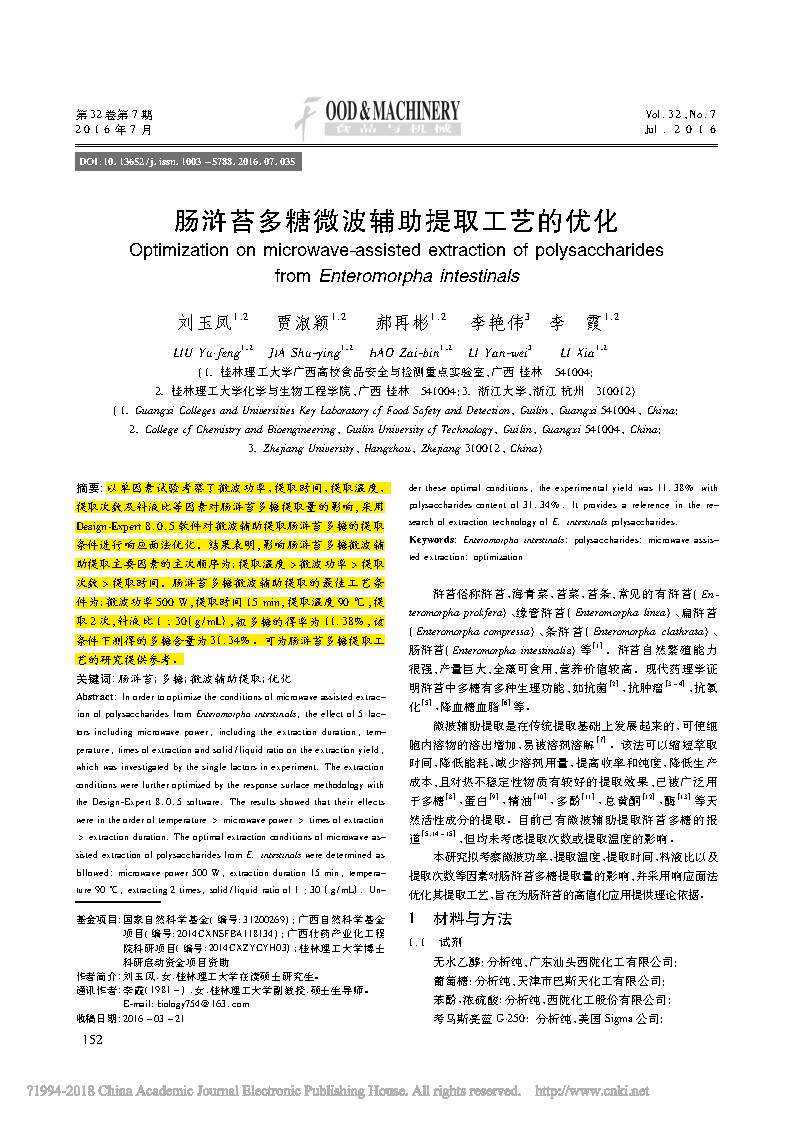

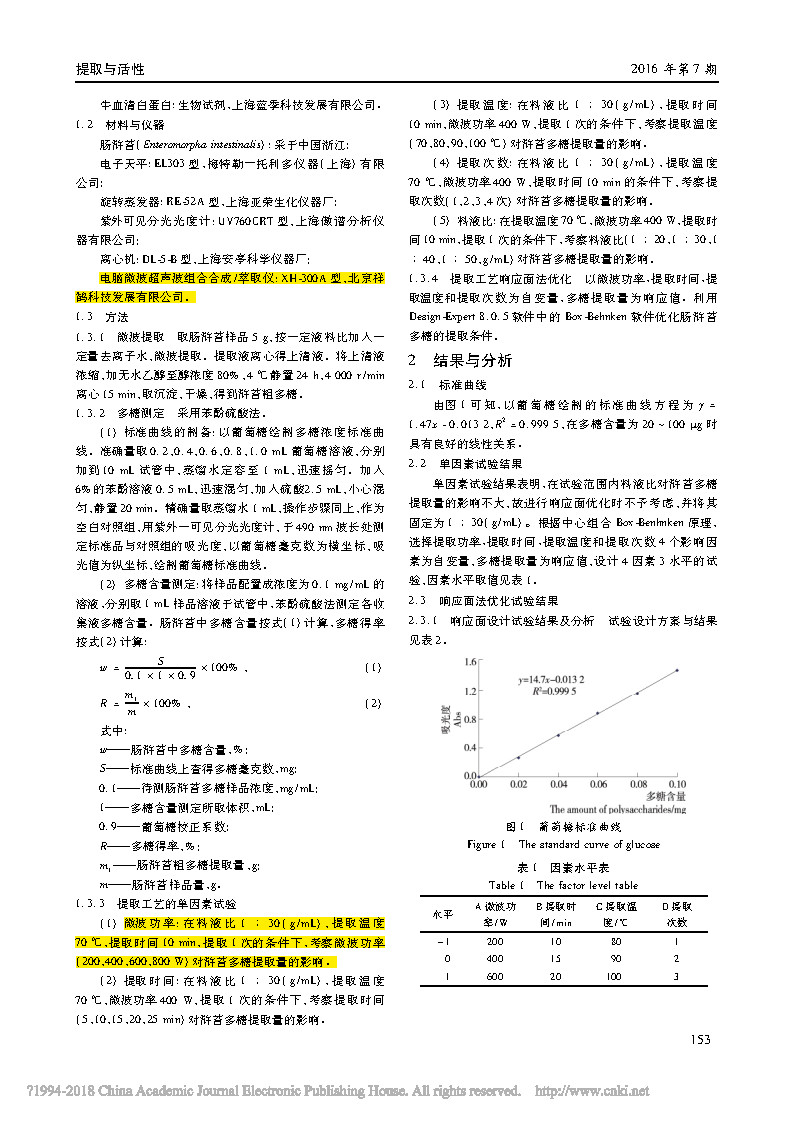

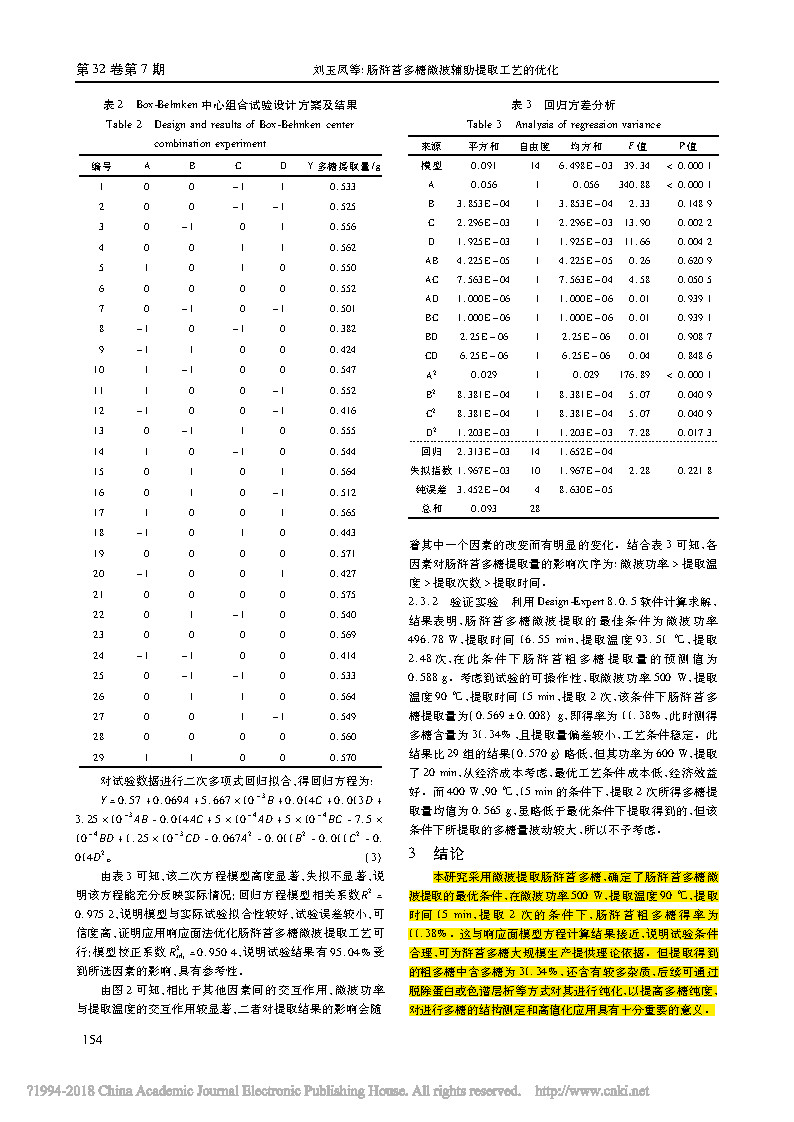

The effects of microwave power, extraction time, extraction temperature, extraction times and ratio of material to liquid on the extraction amount of polysaccharides were studied by single factor experiment. Microwave-assisted extraction of intestinal moss was carried out by Design-Expert 8.0.5 software. The extraction conditions of polysaccharides were optimized by response surface methodology. The results showed that the main order of the main factors affecting the microwave-assisted extraction of polysaccharides from the polysaccharides were: extraction temperature > microwave power > extraction times > extraction time. The optimum conditions for microwave-assisted extraction of polysaccharides from Brassica oleracea L. were: microwave power 500 W, extraction time 15 min, extraction temperature 90 °C, extraction 2 times, ratio of material to liquid 130 (g / mL), yield of crude polysaccharide The ratio of polysaccharide measured under this condition was 11.34%. It can provide reference for the research of the extraction process of polysaccharides from the canola.

Fig.1/3↑

Fig.2/3↑

Fig.3/3↑

In this study, the microwave extraction of polysaccharides from the polysaccharides was studied, and the optimal conditions for microwave extraction of polysaccharides from the polysaccharides were determined. The microwaves were 500 W, the extraction temperature was 90 °C, the extraction time was 15 min, and the extraction was performed twice. The yield of polysaccharide was 11.38%. This is close to the calculation results of the response surface model equation, indicating that the experimental conditions are reasonable, which can provide a theoretical basis for the large-scale production of Brassica polysaccharide. However, the crude polysaccharide obtained by the extraction contains 31.34% polysaccharide, and contains more impurities, which can be purified by removing protein or chromatography to improve the purity of the polysaccharide and determine the structure of the polysaccharide. High-value applications are of great significance.

Microwave power: Under the conditions of solid-liquid ratio (1,.30 (g / mL), extraction temperature of 70 °C, extraction time of 10 min, and extraction once, the microwave power (200, 400, 600, 800 W) was investigated. The effect of the amount of extraction.

京ICP备15050585号

京ICP备15050585号