- 路 Microwave

- 路 Atmospheric Pressure Microwave 路 Pressure Microwave 路 Parallel Microwave

- 路 Ultrasonic 路Low Temperature Ultrasound

- 路 Ultraviolet Light

- 路 Microwave Heating 路 Atmospheric Pressure Synthesis 路 Atmospheric Pressure Catalysis 路 Atmospheric Pressure Extraction

- 路 Sample Preparation 路 Microwave Digestion

- 路 Soil Digestion 路 High Pressure Synthesis

- 路 Solid Phase Synthesis

- 路 Organic Synthesis

- 路 Ionic Liquid Synthesis

- 路 Degradation Of Natural Organic Matter

- 路 Natural Product Extraction / Purification

河北祥鹄科学仪器有限公司

300UL Catalytic conversion of xylose to furfural by tin-loaded montmorillonite in ionic liquid

This paper, completed by a research scholar at South China University of Technology, discusses papers on the catalytic conversion of xylose to furfural by tin-loaded montmorillonite in ionic liquids, and is published in the important journal Paper

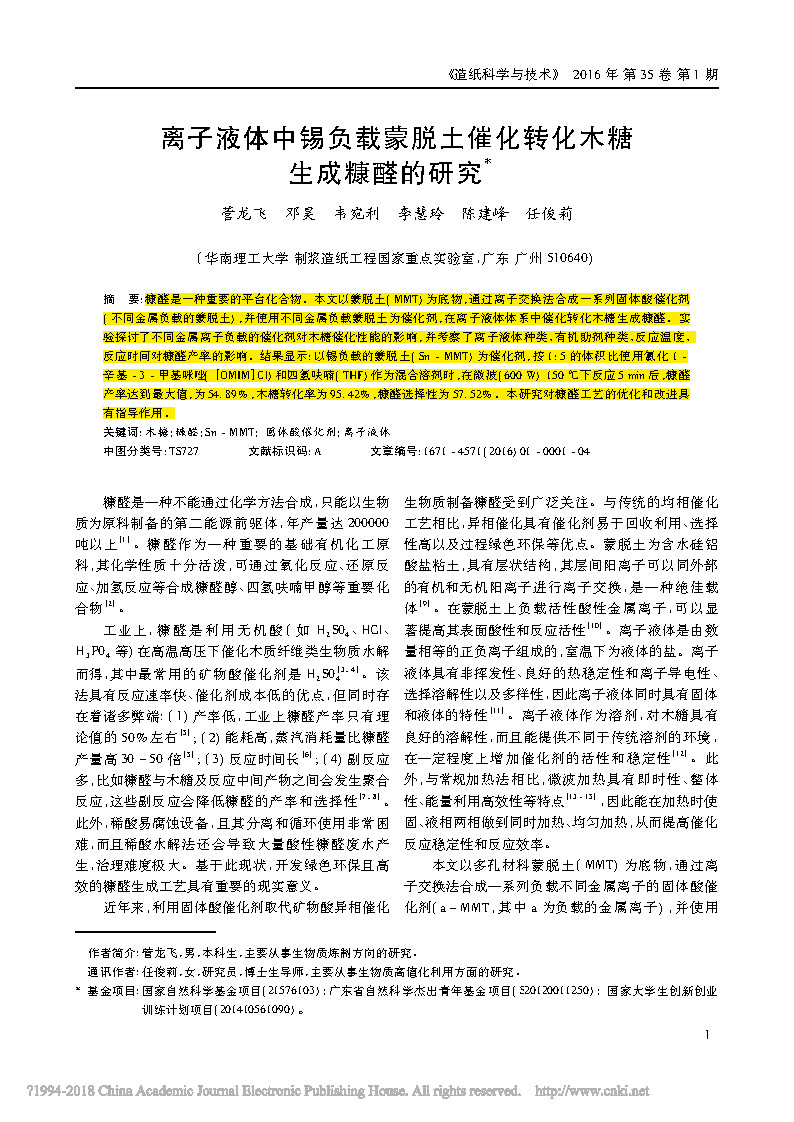

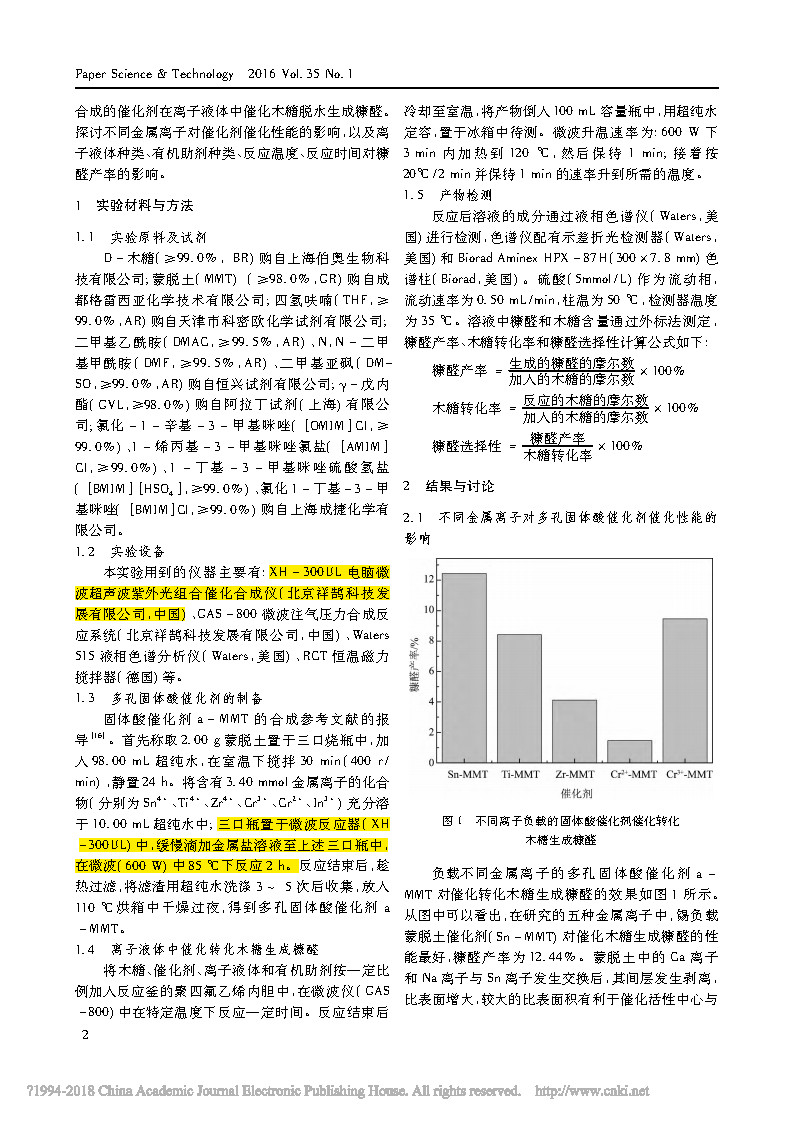

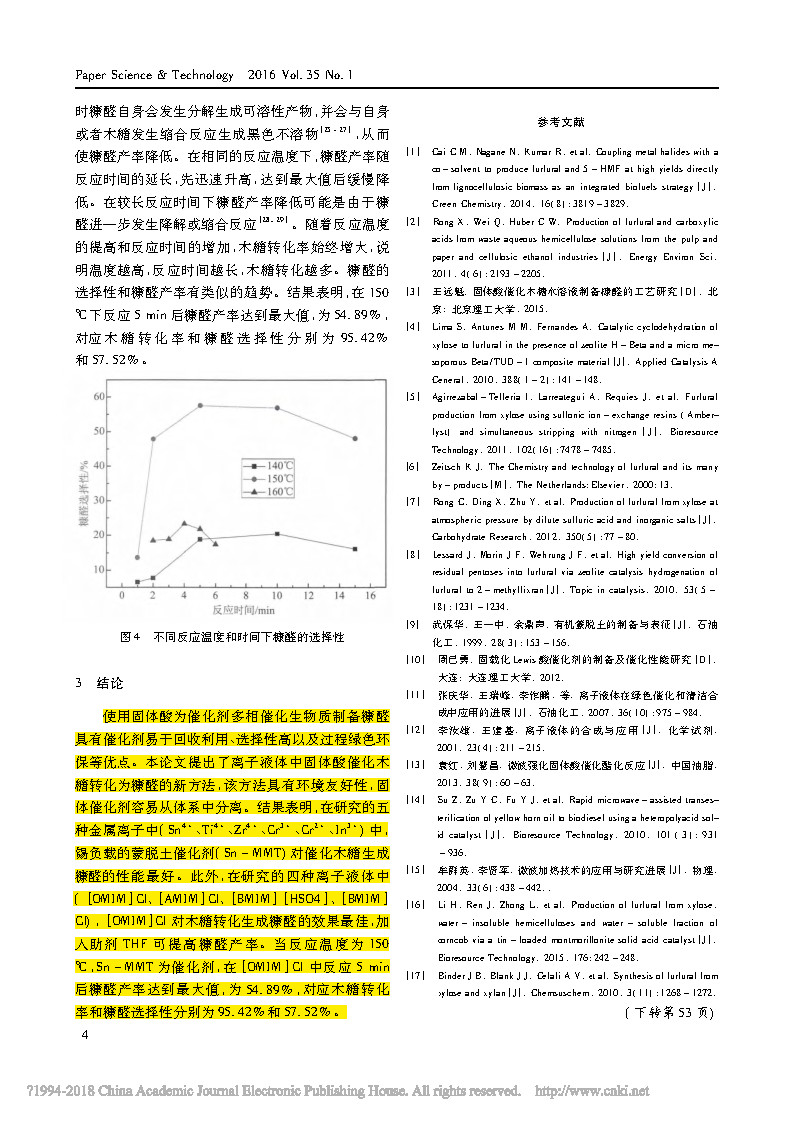

Furfural is an important platform compound. In this paper, a series of solid acid catalysts (montmorillonite with different metal loading) were synthesized by ion exchange method using montmorillonite (MMT) as a substrate, and catalytic conversion was carried out in an ionic liquid system using different metal-loaded montmorillonite as a catalyst. Xylose produces furfural. The effects of different metal ion supported catalysts on the catalytic performance of xylose were investigated. The effects of ionic liquid types, organic additives, reaction temperature and reaction time on the yield of furfural were investigated. The results showed that tin-loaded montmorillonite (Sn-MMT) was used as a catalyst, and 1-octyl-3-methylimidazolium chloride ([OMIM] Cl) and tetrahydrofuran (THF) were used in a volume ratio of 1:5. When the solvent is mixed, the reaction is carried out in a microwave (600 W) at 150 ° C for 5 min, and the yield of the furfural reaches a maximum of 54.89%, the conversion of xylose is 95.42%, and the selectivity of furfural is 57.52%. This study has a guiding role in the optimization and improvement of the furfural process.

Fig.1/3↑

Fig.2/3↑

Fig.3/3↑

The use of solid acid as catalyst for heterogeneous catalytic biomass to prepare furfural has the advantages of easy recycling, high selectivity and green process. In this paper, a new method for the conversion of xylose to furfural by solid acid in ionic liquid is proposed. The method is environmentally friendly and the solid catalyst is easily separated from the system. The results show that among the five metal ions studied (Sn4, Ti4 +, Zr4 +, Cr3 +, Cr2 +, In3 + ), tin-supported montmorillonite catalyst (Sn-MMT) catalyzes the formation of furfural from xylose. The best performance. In addition, among the four ionic liquids studied ([OMIM]Cl[AMIM] Cl, [BMIM][HSO4], [BMIM]Cl), [OMIM]Cl has the best effect on the conversion of xylose to furfural. The THF can increase the yield of furfural. When the reaction temperature is 150°C, Sn-MMT is the catalyst, and the yield of furfural reaches a maximum after 5 minutes of reaction in [OMIM]Cl, which is 54.89%, corresponding to xylose conversion and furfural selectivity of 95.42.% and 57.52%.

Solid acid catalysts are reported in the synthesis of a-MMT [16]. First weigh 2.00 g of montmorillonite in a three-necked flask, add 98. 00 mL of ultrapure water, stir at room temperature for 30 min (400 r / min), and let stand for 24 h. The compound containing 3.40 mmol of metal ions (Sn4+, Ti4+, Zr4+, Cr3+, Cr2+, In3+, respectively) was sufficiently dissolved in 10.00 mL of ultrapure water; the three-necked flask was placed in a microwave reactor (XH-300UL) The metal salt solution was slowly added dropwise to the above three-necked flask, and reacted at 85 ° C for 2 h in a microwave (600 W). After the completion of the reaction, the filter residue was washed with ultrapure water for 3 to 5 times, and collected, and dried in an oven at 110 ° C overnight to obtain a porous solid acid catalyst a-MMT.

京ICP备15050585号

京ICP备15050585号