- 路 Microwave

- 路 Atmospheric Pressure Microwave 路 Pressure Microwave 路 Parallel Microwave

- 路 Ultrasonic 路Low Temperature Ultrasound

- 路 Ultraviolet Light

- 路 Microwave Heating 路 Atmospheric Pressure Synthesis 路 Atmospheric Pressure Catalysis 路 Atmospheric Pressure Extraction

- 路 Sample Preparation 路 Microwave Digestion

- 路 Soil Digestion 路 High Pressure Synthesis

- 路 Solid Phase Synthesis

- 路 Organic Synthesis

- 路 Ionic Liquid Synthesis

- 路 Degradation Of Natural Organic Matter

- 路 Natural Product Extraction / Purification

河北祥鹄科学仪器有限公司

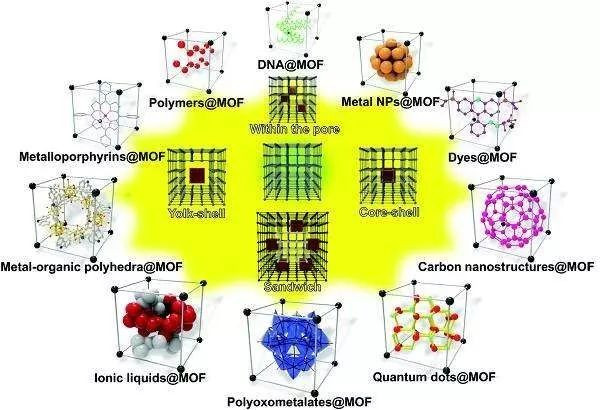

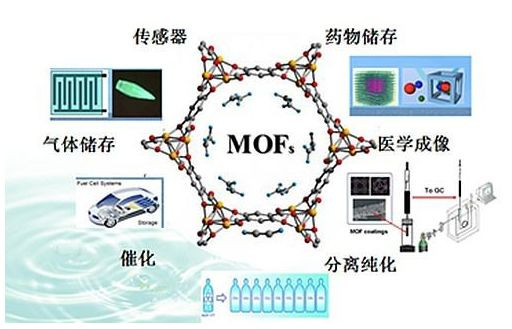

Application of Microwave assisted Synthesis in [MOFs material] Synthesis

Organometallic frame compound (MOFs) is a kind of crystal material with periodic network structure formed by self-assembly process of inorganic metal ions and organic ligands.

The synthesis methods of organometallic frame compound (MOFs) are diverse, including hydrothermal synthesis, ultrasonic synthesis, electrochemical synthesis and mechanical synthesis.

The common disadvantages of these methods are: high temperature, high pressure, long reaction period, complicated operation, etc.

01

Volatilization method is the most traditional and simple method of synthesizing metal complexes. The organic ligand and the metal salt are dissolved in a benign solution, placed, and volatilized by a solvent to precipitate crystals.。

02

(a) Interfacial diffusion method: the organic ligands and metal salts were dissolved in two solvents with different densities, and the solution with lower density was slowly laid on the liquid surface of the solution with higher density, which was sealed.

Near the interface, the complex crystals may be formed near the solution interface by solvent diffusion.

(b)Steam diffusion method: dissolving organic ligands and metal salts in a benign solvent, using a volatile solvent that is volatile,

such as diethyl ether, pentane, hexane, acetone, etc., diffuse into a benign solution to reduce the solubility of the complex to form a complex single crystal.

03

Hydrothermal / solvothermal synthesis is the most effective way to synthesize MOFs. Hydrothermal / solvothermal synthesis means that the ligands, metal salts and reaction solvents are put into the reaction vessel together.

At high temperature and high pressure (generally within 300 ℃), the solubility of each component is minimized, and the viscosity of the solvent decreases, which leads to the enhancement of diffusion, which makes the complexes tend to crystallize and precipitate.

Large skeleton organic ligands with low solubility at room temperature and atmospheric pressure are suitable for hydrothermal / solvothermal method. In general, the crystals synthesized by this method are easier to generate a high dimensional frame structure than the reaction at room temperature.

The reaction vessel used in the synthesis of water heat/ solvent heat method can be divided into two methods: reaction vessel method and vacuum seal tube method.

(a) Reactor method: organic ligands, metal salts and solvents are mixed in a certain proportion and sealed in the reactor lined with PTFE.

The reactor is generally placed in the oven, according to the procedures set up and cooling process, the final precipitation of crystals. Among them, the high pressure produced under the high temperature conditions, make it difficult to dissolve at room temperature, dissolve gradually, participate in the reaction, form the complex.

Therefore, this method can make up for the deficiency of reaction at room temperature, increase the synthetic route and method of the complex, and make the structure of the complex more diversified. At present, this method is commonly used in hydrothermal / solvothermal synthesis because of the mature preparation technology of reactor.

(b) Vacuum-sealing method: adding an organic ligand and a metal salt, a solvent and the like into a quartz glass tube with one end open at one end, cooling the quartz glass tube in liquid nitrogen, and freezing the solution for vacuum processing.

Under vacuum condition, the open end of quartz glass tube is sealed to form a closed vacuum environment. Put it into a set temperature control program precision temperature control furnace, to be cooled to room temperature after cooling, precipitate crystals.

Because the inner wall of glass tube is more delicate and provides oxygen free environment, this method is suitable for the growth of large skeleton ligand complexes, and is conducive to the formation of single crystals with large shape, complete structure and excellent quality. It is a widely used synthesis method at present.

It is worth noting that organic ligands, metal salts or solvents have different saturated vapor pressures, and the problem of quartz tube rupture is easy to occur during the synthesis of MOFs at high temperature.

The efficiency of MOFs synthesis can be improved by reducing and controlling the loading amount of samples in quartz tubes and adopting a high vacuum sealing method with a large wall thickness quartz tube.

04

Microwave synthesis of MOFs has the advantages of simple operation, high energy utilization, environmental friendliness, short reaction period and fast reaction speed due to the selective heating of the object by microwave.

The structure of MOFs synthesized by microwave synthesis is even better than that of MOFs synthesized by traditional method.

4.1 The metal frame structure of microwave assisted synthesis of nano-pore is used to adsorb carbon dioxide and nitrogen gas, and good results are obtained.

4.2 MOFs thin films were successfully synthesized by microwave method in a short period of time. The surface was compact and uniform, smooth and smooth, the quantum yield was increased, and the film could be recycled.

4.3 Microwave synthesis of MOFs materials with higher adsorption energy than surface.

For the synthesis method of MOFs, in addition to the above four commonly used methods, there are sublimation synthesis method, two-phase synthesis method, ultrasonic synthesis method, ionic liquid method, solid phase reaction method and the like.

In the process of MOFs, a suitable synthetic method can be selected according to the actual needs. With the extensive research of the MOFs, a new synthesis method can be found and applied.

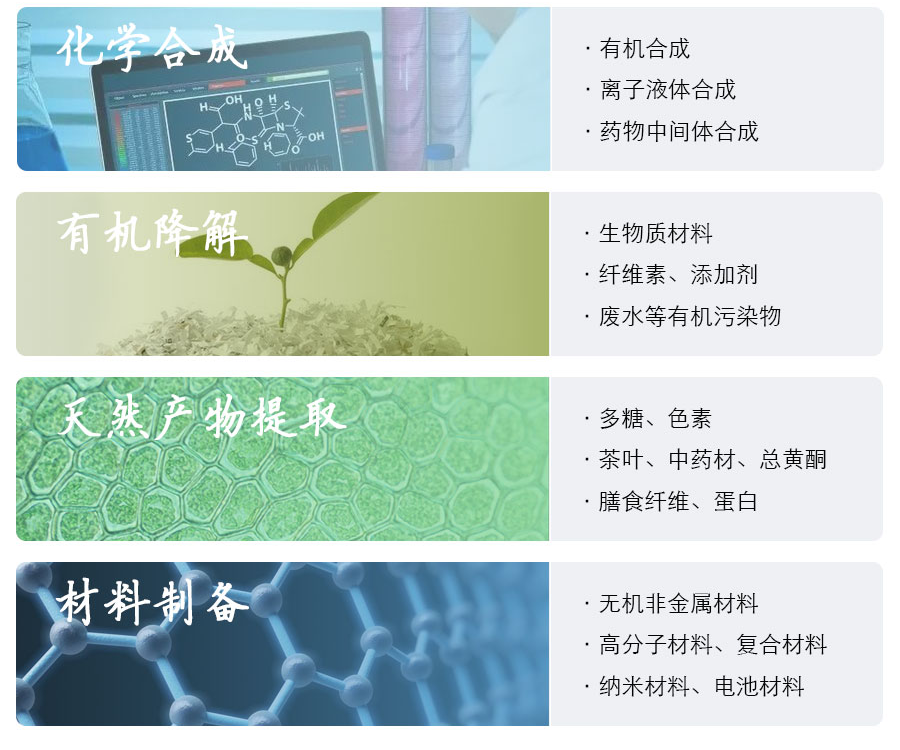

Other typical applications of microwave methods in the preparation of materials include, but are not limited to:

京ICP备15050585号

京ICP备15050585号