- 路 Microwave

- 路 Atmospheric Pressure Microwave 路 Pressure Microwave 路 Parallel Microwave

- 路 Ultrasonic 路Low Temperature Ultrasound

- 路 Ultraviolet Light

- 路 Microwave Heating 路 Atmospheric Pressure Synthesis 路 Atmospheric Pressure Catalysis 路 Atmospheric Pressure Extraction

- 路 Sample Preparation 路 Microwave Digestion

- 路 Soil Digestion 路 High Pressure Synthesis

- 路 Solid Phase Synthesis

- 路 Organic Synthesis

- 路 Ionic Liquid Synthesis

- 路 Degradation Of Natural Organic Matter

- 路 Natural Product Extraction / Purification

河北祥鹄科学仪器有限公司

13 Statistical modeling/optimization and process intensification of microwave-assisted acidified oil esterification

This paper, written by researchers from Shandong University of Technology and others, discusses Statistical modeling/optimization and process intensification of microwave-assisted acidified oil esterification. The paper is published in an important journal < Energy Conversion and Management>. IF:6.377

In recent years, the research work of microwave chemical instrument used in the synthesis of materials has become a hot direction of scientific research, which has been paid great attention to by many scholars!

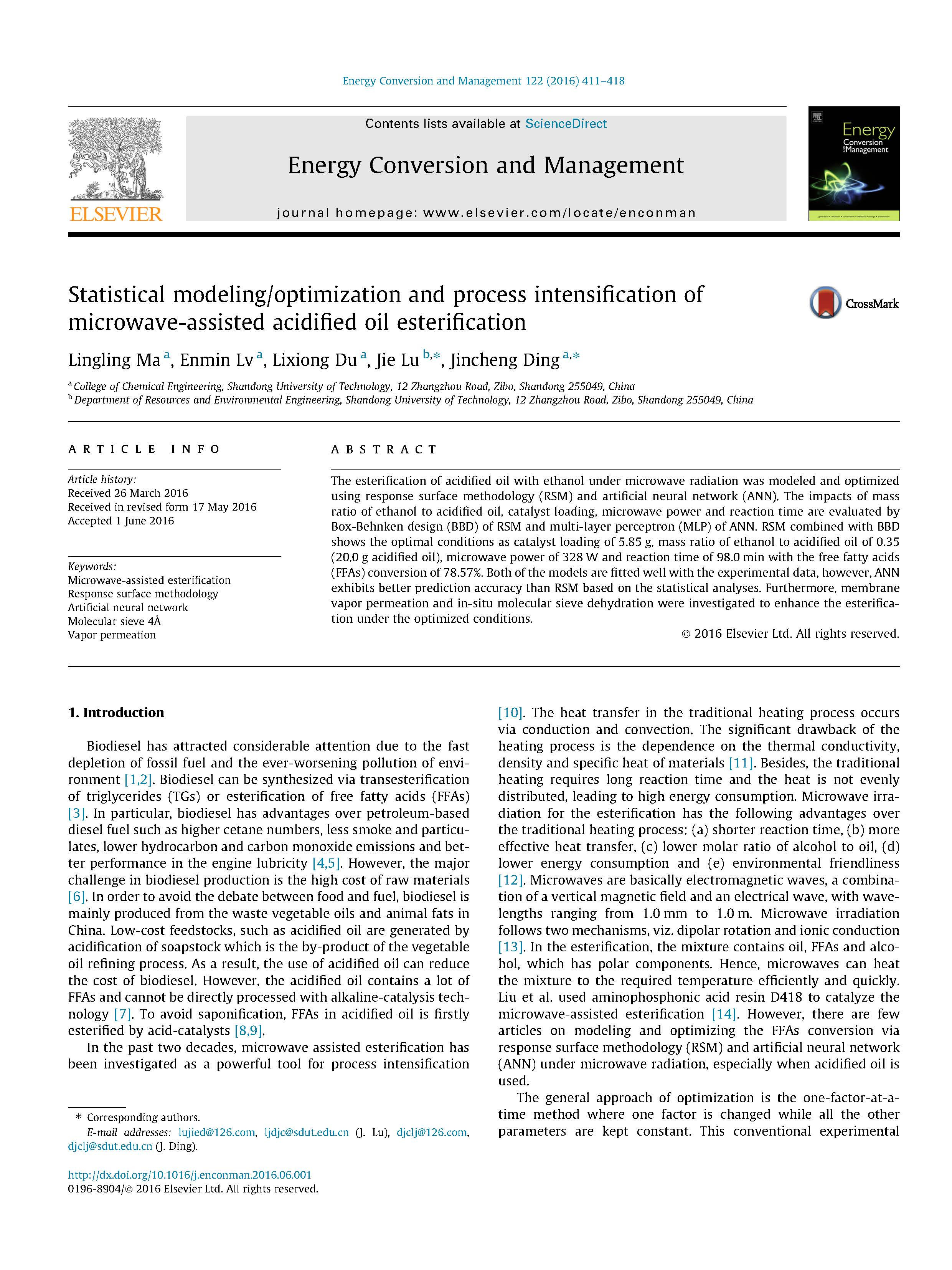

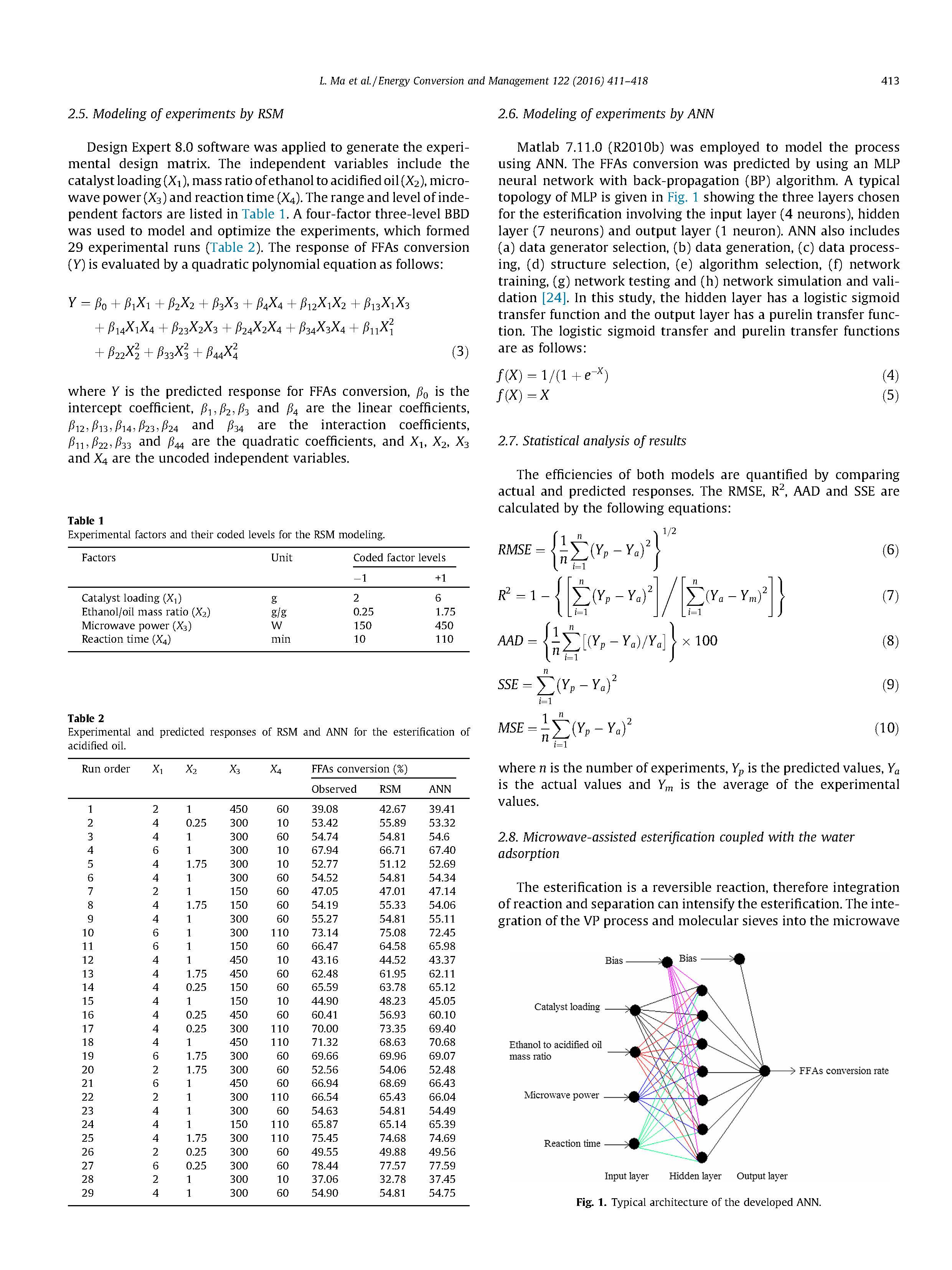

The esterification of acidified oil with ethanol under microwave radiation was modeled and optimized using response surface methodology (RSM) and artificial neural network (ANN). The impacts of mass ratio of ethanol to acidified oil, catalyst loading, microwave power and reaction time are evaluated by Box-Behnken design (BBD) of RSM and multi-layer perceptron (MLP) of ANN. RSM combined with BBD shows the optimal conditions as catalyst loading of 5.85 g, mass ratio of ethanol to acidified oil of 0.35 (20.0 g acidified oil), microwave power of 328W and reaction time of 98.0 min with the free fatty acids (FFAs) conversion of 78.57%. Both of the models are fitted well with the experimental data, however, ANN exhibits better prediction accuracy than RSM based on the statistical analyses. Furthermore, membrane vapor permeation and in-situ molecular sieve dehydration were investigated to enhance the esterification under the optimized conditions.

Fig.1/4↑

Fig.2/4↑

Fig.3/4↑

Fig.4/4↑

In this study, microwave assisted esterification from acidified oil was evaluated and modeled by RSM and ANN. The performance and predictive capabilities of RSM based on the BBD matrix and ANN were compared statistically. Based on the values of RMSE, R2, AAD and SSE, both models are able to predict the experimental data, but ANN is superior over BBD. Furthermore, tubular NaA zeolite membrane and spherical molecular sieve 4Å were used to remove water selectively and continuously under the RSM optimized conditions. These two dehydration approaches improved the FFAs conversion by 20.0% approximately. Therefore, membrane VP and in-situ molecular sieve dehydration are feasible and effective to enhance the esterification under microwave irradiation.

The microwave reactor (XH-200A, Beijing Xianghu Science and Technology Development Co., Ltd., Beijing, China) is used as the source of microwave radiation for transferring the energy to the reactants directly. The system consists of a magnetic stirrer, a reflux condenser connected with an air-cooled condenser and an infrared temperature monitor. The stirring rate was 480 rpm [31]. A three-necked flask (250 ml) was fitted with the air-cooled condenser and the temperature sensor. Considering the security of electromagnetic tube, a beaker of water (100 ml) was settled in the reactor to absorb excess microwave radiation during each experiment.

京ICP备15050585号

京ICP备15050585号