- 路 Microwave

- 路 Atmospheric Pressure Microwave 路 Pressure Microwave 路 Parallel Microwave

- 路 Ultrasonic 路Low Temperature Ultrasound

- 路 Ultraviolet Light

- 路 Microwave Heating 路 Atmospheric Pressure Synthesis 路 Atmospheric Pressure Catalysis 路 Atmospheric Pressure Extraction

- 路 Sample Preparation 路 Microwave Digestion

- 路 Soil Digestion 路 High Pressure Synthesis

- 路 Solid Phase Synthesis

- 路 Organic Synthesis

- 路 Ionic Liquid Synthesis

- 路 Degradation Of Natural Organic Matter

- 路 Natural Product Extraction / Purification

河北祥鹄科学仪器有限公司

202 Conversion of steroid saponins into diosgenin by catalytic hydrolysis using acid-functionalized ionic liquid under microwave irradiation

This paper, written by researchers from Jiangnan University and others, discusses Conversion of steroid saponins into diosgenin by catalytic hydrolysis using acid-functionalized ionic liquid under microwave irradiation. The paper is published in an important journal < Journal of Cleaner Production >. IF:5.651.

In recent years, the research work of microwave chemical instrument used in the synthesis of materials has become a hot direction of scientific research, which has been paid great attention to by many scholars!

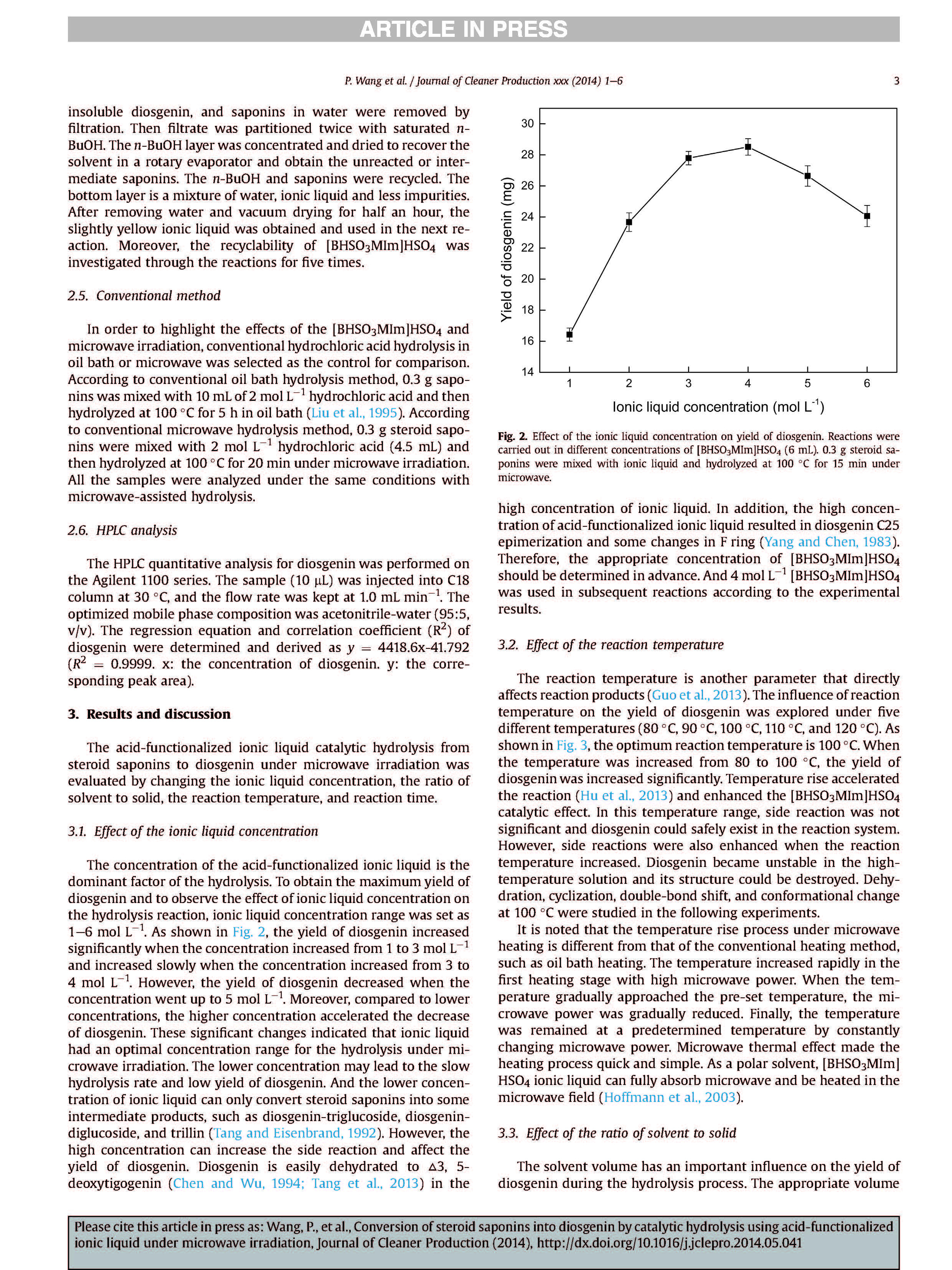

The catalytic hydrolysis with an acid-functionalized ionic liquid under microwave irradiation was successfully developed to convert steroid saponins into diosgenin. The typical acid-functionalized ionic liquid, 1-sulfobutyl-3-methylimidazolium hydrosulfate ([BHSO3MIm]HSO4), was used to evaluate the catalytic efficiency. The results strongly suggested that acid-functionalized ionic liquid under microwave irradiation significantly improved the hydrolysis efficiency of steroid saponins. In addition, we optimized hydrolysis parameters, including the ionic liquid concentration, the ratio of solvent to solid, the reaction temperature, and reaction time. Under the optimal conditions, this approach achieved the highest yield of diosgenin (29.97 ± 0.51 mg) with 0.3 g steroid saponins. Compared with regular hydrochloric acid hydrolysis, the developed approach obtained 96% diosgenin and reduced 93% reaction time, indicating that the catalytic hydrolysis with an acid-functionalized ionic liquid under microwave irradiation had a broad application prospect in diosgenin production.

Fig.1/4↑

Fig.2/4↑

Fig.3/4↑

Fig.4/4↑

The catalytic hydrolysis with an acid-functionalized ionic liquid under microwave irradiation methodwas successfully developed to convert steroid saponins into diosgenin. The typical 1-sulfobutyl-3- methylimidazolium hydrosulfate ionic liquid ([BHSO3MIm]HSO4) was used and hydrolysis conditions were optimized. Optimal conditions were provided as follows: 4 mol L 1 [BHSO3MIm]HSO4, the ratio of solvent to solid of 15:1, the reaction temperature at 100 C, and reaction time of 20 min. Under the optimal conditions, this approach gained the highest yield of diosgenin of 29.97 ± 0.51 mg with 0.3 g steroid saponins. Compared with the regular hydrochloric acid hydrolysis, the proposed approach has the following three advantages. Firstly, the proposed approach obtained approximate yield as the regular hydrochloric acid hydrolysis and reduced 93% reaction time. Secondly, all hydrolysis solvents were environment-friendly and recyclable. Acid-functionalized ionic liquid replaced the traditional hydrochloric acid and greatly alleviated environment pollution. Thirdly, [BHSO3MIm]HSO4 ionic liquid was stable and effective with only a slight decrease after three cycles. And the unreacted substrates were also recycled by effective recycling method. In summary, this method showed a broad application prospect in diosgenin production.

XH-800B intelligent microwave workstation with an output power of 0e1000 W was purchased from Beijing Xianghu Science and Technology Development Co., Ltd. (Beijing). The temperature of the reaction mixture was monitored and kept constant (±1 C). A positive & negative controlled rotary plate was placed on the floor of the microwave cavity and six samples could be processed at the same time. In the actual experiments, the reaction temperaturewas kept constant through fluctuant microwave power.

京ICP备15050585号

京ICP备15050585号