- 路 Microwave

- 路 Atmospheric Pressure Microwave 路 Pressure Microwave 路 Parallel Microwave

- 路 Ultrasonic 路Low Temperature Ultrasound

- 路 Ultraviolet Light

- 路 Microwave Heating 路 Atmospheric Pressure Synthesis 路 Atmospheric Pressure Catalysis 路 Atmospheric Pressure Extraction

- 路 Sample Preparation 路 Microwave Digestion

- 路 Soil Digestion 路 High Pressure Synthesis

- 路 Solid Phase Synthesis

- 路 Organic Synthesis

- 路 Ionic Liquid Synthesis

- 路 Degradation Of Natural Organic Matter

- 路 Natural Product Extraction / Purification

河北祥鹄科学仪器有限公司

242 Ultrasonic assisted microwave synthesis of poly (Chitosan-co-gelatin)/ polyvinyl pyrrolidone IPN hydrogel

This paper, written by researchers from Ningbo University of Technology and others, discusses Ultrasonic assisted microwave synthesis of poly (Chitosan-co-gelatin)/ polyvinyl pyrrolidone IPN hydrogel. The paper is published in an important journal < Ultrasonics Sonochemistry >. IF:6.012.

In recent years, the research work of microwave chemical instrument used in the synthesis of materials has become a hot direction of scientific research, which has been paid great attention to by many scholars!

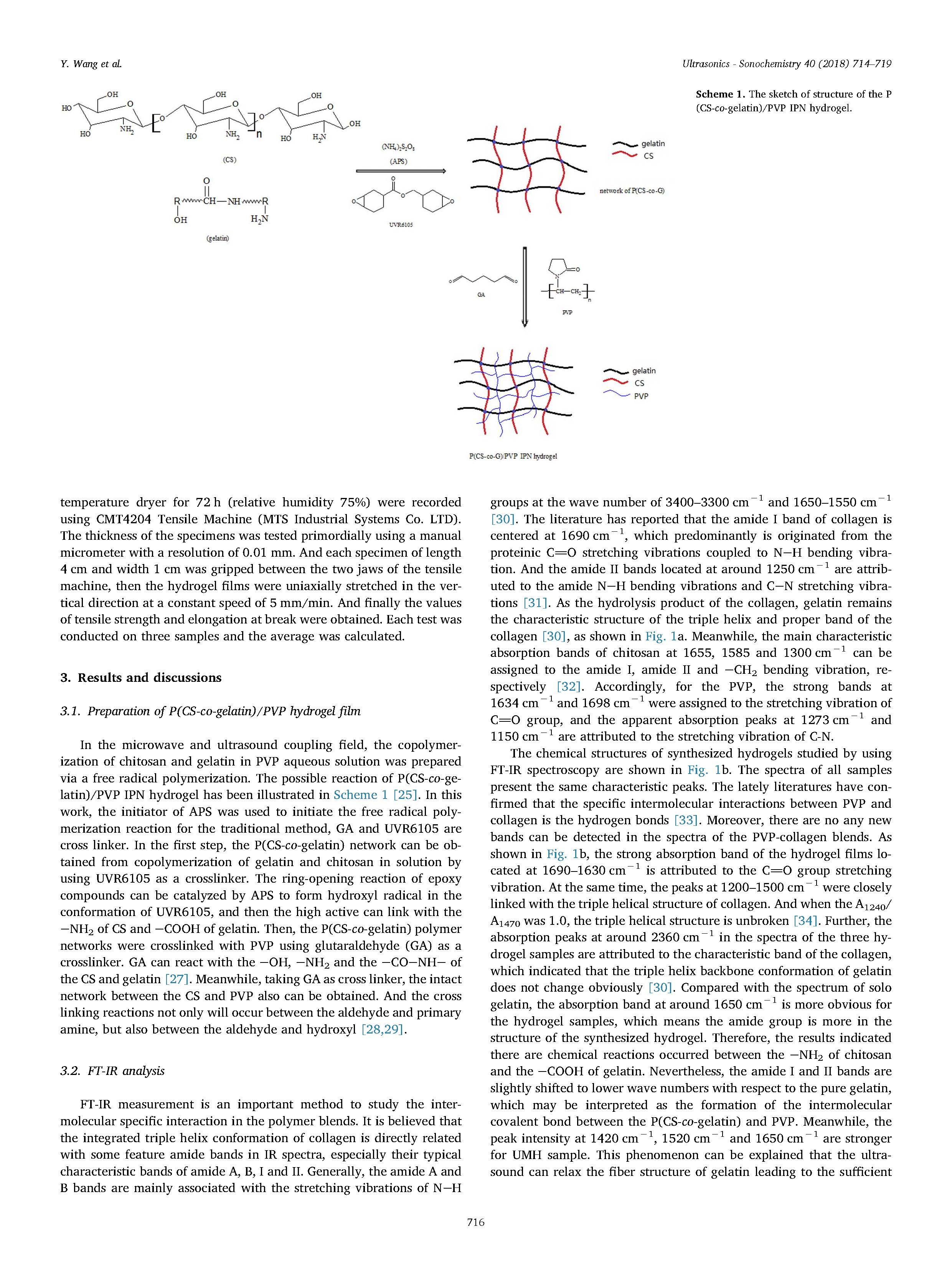

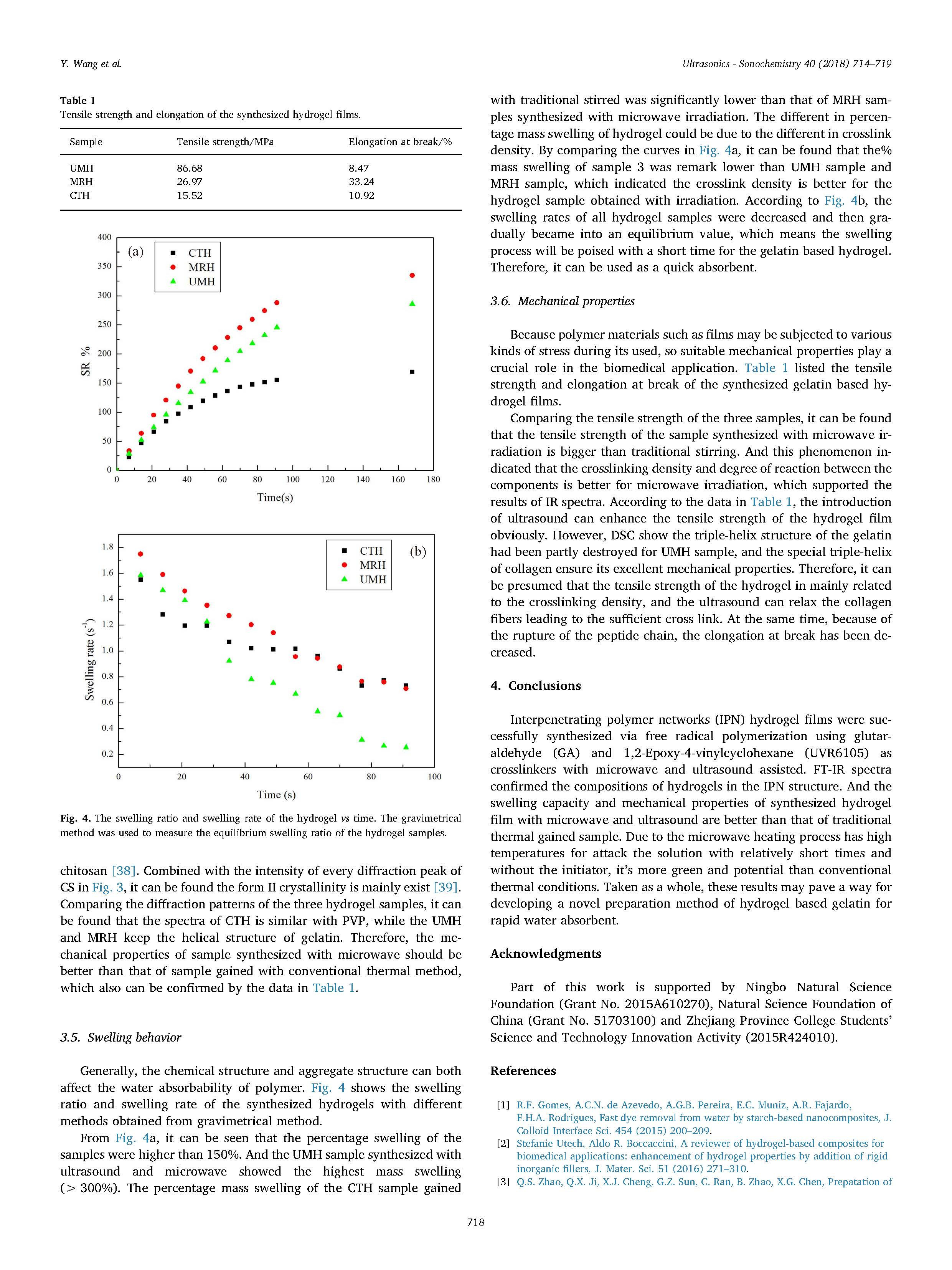

The hydrogels based on gelatin cross-linked with chitosan (CS) and polyvinyl pyrrolidone (PVP) were synthesized using microwave and ultrasonic coupling technique in this study. This interpenetrating polymer network (IPN) hydrogels were cross-linked by glutaraldehyde and 1,2-Epoxy-4-vinylcyclohexane. The presence of function groups in the structure of hydrogel films were confirmed using Fourier transform infrared spectroscopy (FTIR), thermal stability was measured by DSC, and the swelling behaviors were measured gravimetrically in distilled water at the temperature of 27 °C. At last, the mechanical properties were tested. The results showed that the hydrogel prepared with microwave and ultrasonic exhibited the highest tensile strength (86.68 MPa), comparing with the hydrogel prepared with traditional method and only microwave reactive field. The FT-IR and XRD results showed that the chemical reactions occurred between the eNH2 of chitosan and the eCOOH of gelatin, and the introduction of ultrasound can improve the reaction rate. The hydrogel film gained in microwave and ultrasonic coupling field has the best combination properties. Therefore, the new microwave-ultrasonic coupling technique is the potential technology to prepare the new hydrogel due to less synthesis time.

Fig.1/4↑

Fig.2/4↑

Fig.3/4↑

Fig.4/4↑

Interpenetrating polymer networks (IPN) hydrogel films were successfully synthesized via free radical polymerization using glutaraldehyde (GA) and 1,2-Epoxy-4-vinylcyclohexane (UVR6105) as crosslinkers with microwave and ultrasound assisted. FT-IR spectra confirmed the compositions of hydrogels in the IPN structure. And the swelling capacity and mechanical properties of synthesized hydrogel film with microwave and ultrasound are better than that of traditional thermal gained sample. Due to the microwave heating process has high temperatures for attack the solution with relatively short times and without the initiator, it’s more green and potential than conventional thermal conditions. Taken as a whole, these results may pave a way for developing a novel preparation method of hydrogel based gelatin for rapid water absorbent.

Chitosan was dissolved in 20 mL 1% acetic acid solution, 1.0 g gelatin was added into the solution to make the ratio of gelatin and chitosan is 2:1. And then about 0.05 g 1,2-Epoxy-4-vinylcyclohexane (UVR6105) was dropped into the three-necked bottle. 1.0 g PVP powder was dissolved in 10 mL distilled water with glutaraldehyde as the crosslinking agent. And the resulting solution was reacted at three kinds of conditions. One is the conventional thermal condition with water bath taking APS as the initiator, and the synthesized hydrogel named with CTH. The second method is the microwave radiation, and power of microwave is 500 W, the gained sample was named with MRH. The third reaction condition is the coupling reaction field with microwave and ultrasonic wave (XH-300UL Microwave-Ultrasonic-UV synthesis, Beijing Xianghu Technology Limited Co., China), and the power of microwave and ultrasonic wave was 300 W and 500 W, respectively, the sample was named with UMH. The mixture solution was processed at 60 °C, and the reaction time is 120 min, 30 min and 15 min for these three methods. And then the obtained thick dispersion was poured onto a petri dish. The solvent was allowed to evaporate at room temperature for 2 days and the resulting films were further dried in vacuum at 50 °C for 8h.

京ICP备15050585号

京ICP备15050585号