- 路 Microwave

- 路 Atmospheric Pressure Microwave 路 Pressure Microwave 路 Parallel Microwave

- 路 Ultrasonic 路Low Temperature Ultrasound

- 路 Ultraviolet Light

- 路 Microwave Heating 路 Atmospheric Pressure Synthesis 路 Atmospheric Pressure Catalysis 路 Atmospheric Pressure Extraction

- 路 Sample Preparation 路 Microwave Digestion

- 路 Soil Digestion 路 High Pressure Synthesis

- 路 Solid Phase Synthesis

- 路 Organic Synthesis

- 路 Ionic Liquid Synthesis

- 路 Degradation Of Natural Organic Matter

- 路 Natural Product Extraction / Purification

河北祥鹄科学仪器有限公司

100B Optimization of Microwave-assisted Extraction of Ferulic Acid from Xinjiang Ferulic Root by Response Surface Method and Its Antioxidant Activity in Vitro

This research was completed by a research scholar at the School of Life and Environmental Sciences of the Central University for Nationalities. The paper discusses the optimization of the microwave-assisted extraction process and the antioxidant activity of the ferulic acid in Xinjiang by the response surface test. It was published in the important journal

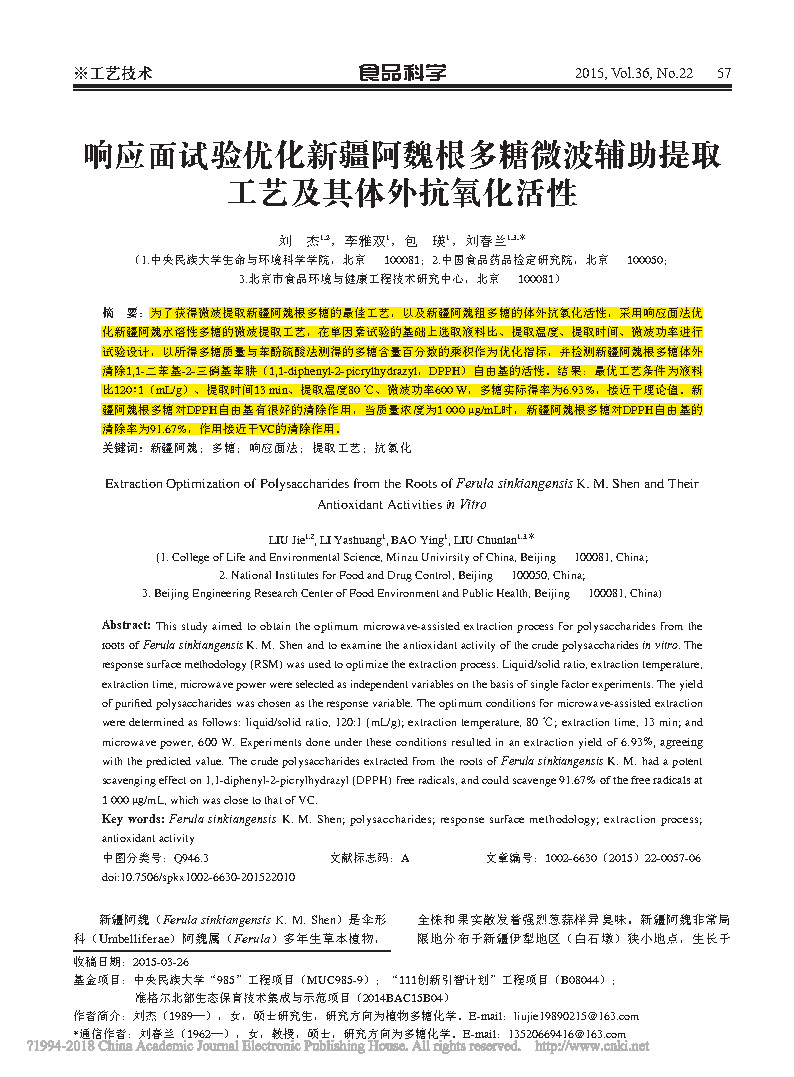

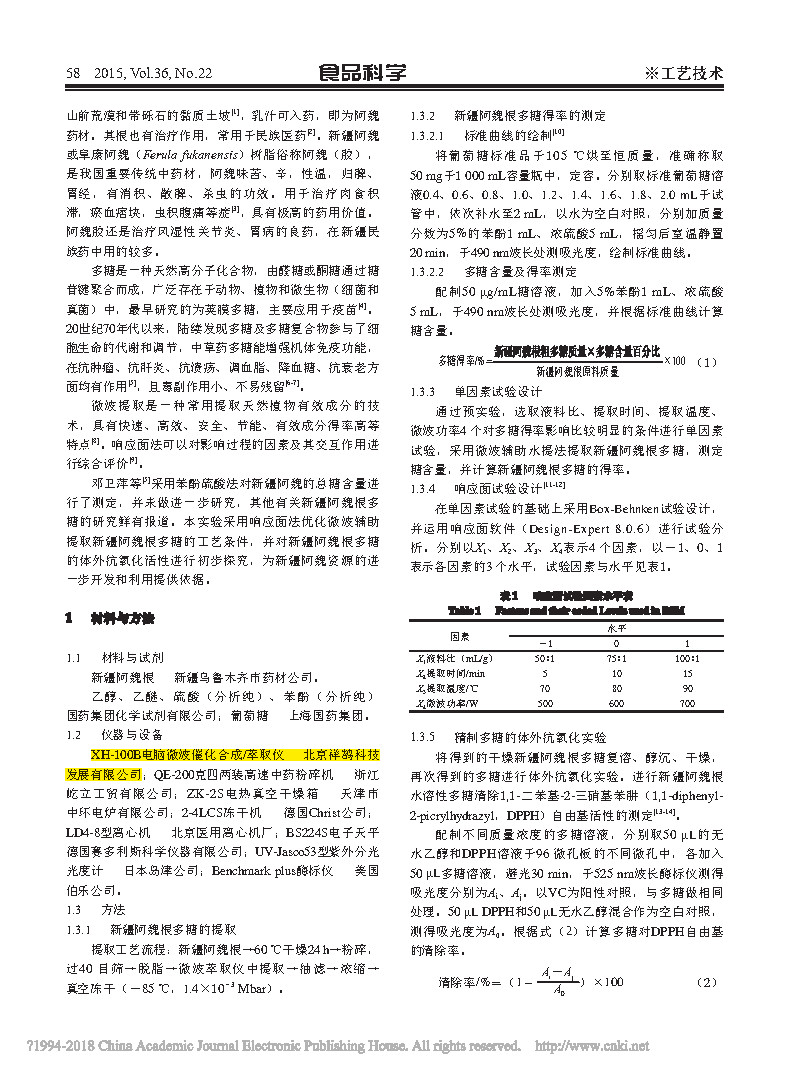

In order to obtain the best technology of microwave extraction of ferulic acid from Xinjiang, and the in vitro antioxidant activity of crude polysaccharides from Xinjiang, the microwave extraction process of water-soluble polysaccharides from Xinjiang ferulic acid was optimized by response surface methodology, and selected on the basis of single factor experiment. The liquid-to-material ratio, extraction temperature, extraction time and microwave power were designed and tested. The product of the mass of the obtained polysaccharide and the percentage of polysaccharide content measured by phenol sulfuric acid method was used as an optimization index, and the in vitro clearance of Xinjiang ferulic acid polysaccharide was detected. Activity of 1,1-diphenyl-2-picrylhydrazyl (DPPH) free radicals. Results: The optimum process conditions were liquid to material ratio of 120:1 (mL/g), extraction time of 13 min, extraction temperature of 80 °C, microwave power of 600 W, and the actual yield of polysaccharide was 6.93%, which was close to the theoretical value. Xinjiang ferulic acid polysaccharide has a good scavenging effect on DPPH free radicals. When the concentration is 1 000g/mL, the clearance rate of DPPH free radicals in Xinjiang ferulic root polysaccharide is 91.67%, which is close to the scavenging effect of VC.

Fig.1/3↑

Fig.2/3↑

Fig.3/3↑

Using Fick's law, the kinetic model of KGM extraction was established by mass transfer mechanism analysis. KGM extraction in konjac is a very complicated process. From the kinetic model and experimental data analysis, the rate constant is not only related to temperature, but also to medicinal materials. The particles themselves are related and are mainly controlled by internal diffusion. After data fitting, the final model y = A1* exp( - x t 1 ) + y0 conforms to the dynamic equation and the model can describe the extraction process more accurately. Using the Arrhenius equation, the activation energy Ea = 1.996 × 104J mol and the velocity number k0 = 29.3045 were further obtained. It was finally determined that the model can better describe the kinetic equation of the extraction process. This result can be extracted from KGM. The choice of process design and operating conditions provides a theoretical basis.

In this experiment, the response surface analysis was carried out by four factors: liquid-to-material ratio, extraction temperature, extraction time and microwave power. The results of variance analysis of regression model showed that the effects of various factors on polysaccharide yield were significant, and the order of influence was extraction temperature>liquid Feed ratio > extraction time > microwave power. The optimum conditions for microwave extraction of water-soluble polysaccharides from Xinjiang were as follows: response ratio: 120:1 (mL/g), extraction time 13 min, extraction temperature 80°C, microwave power 600 W. The actual yield of polysaccharides from Xinjiang fern root is 6.93%, which is close to the predicted value of polysaccharide yield. The results of in vitro antioxidant experiments showed that the polysaccharides from Xinjiang ferulic root had a good scavenging effect on DPPH free radicals and were equivalent to the antioxidant properties of VC. In view of the antioxidant activity of Xinjiang ferulic acid polysaccharide, it can be applied to the development of related health products, drugs and cosmetics [25].

京ICP备15050585号

京ICP备15050585号