- 路 Microwave

- 路 Atmospheric Pressure Microwave 路 Pressure Microwave 路 Parallel Microwave

- 路 Ultrasonic 路Low Temperature Ultrasound

- 路 Ultraviolet Light

- 路 Microwave Heating 路 Atmospheric Pressure Synthesis 路 Atmospheric Pressure Catalysis 路 Atmospheric Pressure Extraction

- 路 Sample Preparation 路 Microwave Digestion

- 路 Soil Digestion 路 High Pressure Synthesis

- 路 Solid Phase Synthesis

- 路 Organic Synthesis

- 路 Ionic Liquid Synthesis

- 路 Degradation Of Natural Organic Matter

- 路 Natural Product Extraction / Purification

河北祥鹄科学仪器有限公司

88 Enhanced oils and organic solvents absorption by polyurethane foams composites modified with MnO2 nanowires

This paper, written by researchers from Jiangsu University and others, discusses Enhanced oils and organic solvents absorption by polyurethane foams composites modified with MnO2 nanowires. The paper is published in an important journal < Chemical Engineering Journal >. IF:6.735.

In recent years, the research work of microwave chemical instrument used in the synthesis of materials has become a hot direction of scientific research, which has been paid great attention to by many scholars!

The severe environmental and ecological problems, derived from oil spills and organic solvents leakage, have occurred in many parts of the world. It is urgent to seek appropriate ways to resolve oily wastewater and organic solvent pollution. A versatile oil-absorbing material which can separate the oily wastewater effectively and quickly is in high demanded for this issue. In this work, we report a facile and inexpensive to fabricate an effective and recyclable oil-absorbent, namely MnO2 nanowires/polyurethane (PU) foam composites, using a PU sponge as a porous substrate and MnO2 nanowires as modifiers. The hydrothermal method is employed to synthesize MnO2 nanowires and then foaming technology is used to fabricate MnO2 nanowires/PU foam composites. In order to enhance the hydrophobic and oleophilic properties, the surfaces of MnO2 nanowires are chemically modified using silane coupling agent (KH 570). The present MnO2 nanowires/PU foam composites not only effectively separate oils from water as expected, but also possess a very high absorption capacity for the removal of organic solvents from water up to 40.15 times its own weight. More importantly, the obtained MnO2 nanowires/PU foam composites is demonstrated to have excellent oil recoverability and absorbent regenerability, making them versatile and comprehensive absorbents to satisfy various practical oily wastewater and organic solvent separation requirements.

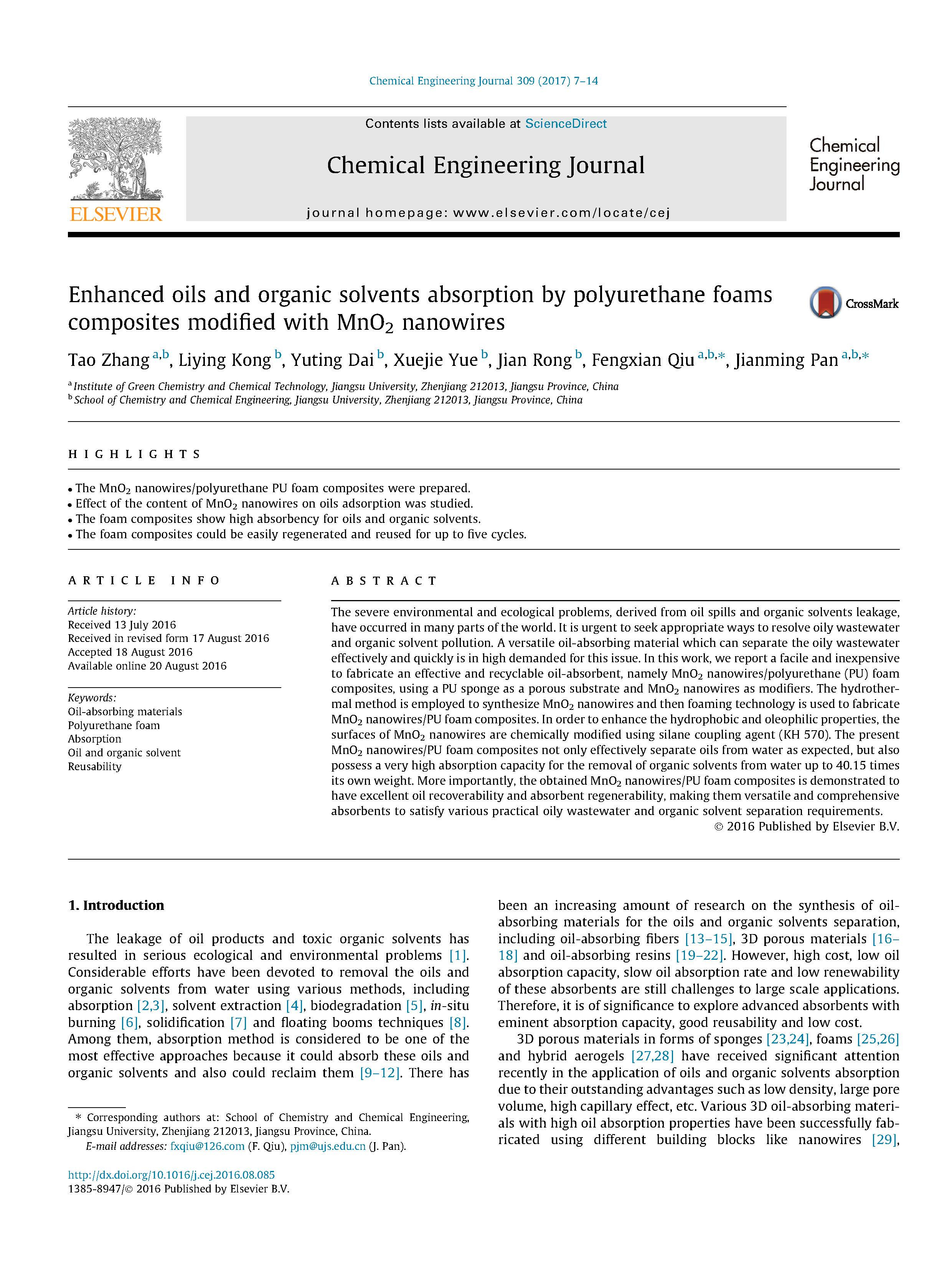

Fig.1/4↑

Fig.2/4↑

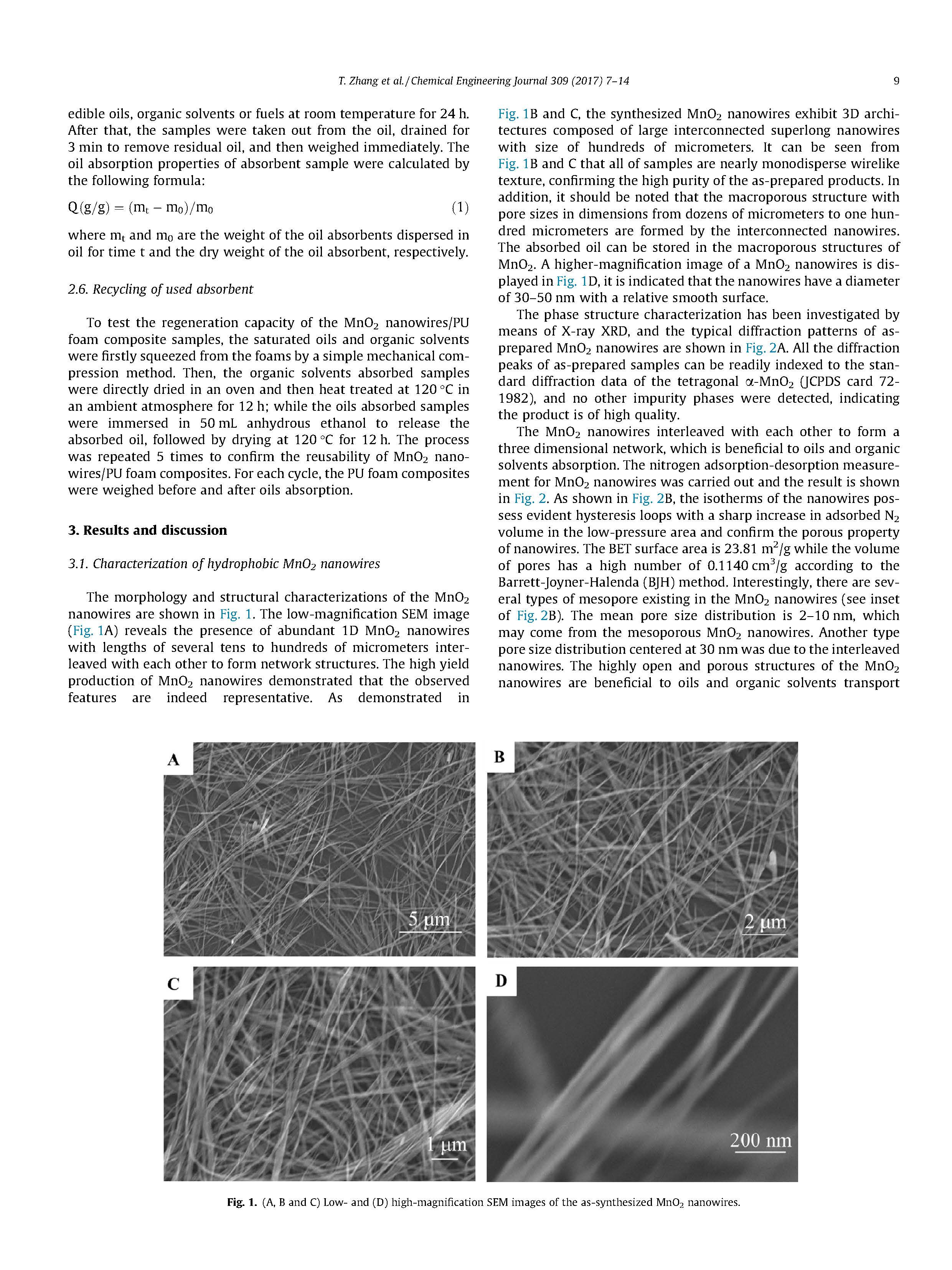

Fig.3/4↑

Fig.4/4↑

In summary, a versatile oil-absorbing material composed of MnO2 nanowires/ PU foams can be fabricated by combined hydrothermal method and foaming technology. The superlong MnO2 nanowires have been synthesized by a hydrothermal method, and the surfaces of MnO2 nanowires are chemically modified using KH 570 to enhance the hydrophobic and oleophilic properties. The relevant results disclosed that the hydrophobic groups are successfully grafted on the surfaces of MnO2 nanowires with water contact angle of 141.85_. The MnO2 nanowires/PU foam composites are fabricated by the polymerization of the NJ-330, IPDI and surfaces modified MnO2 nanowires. It was found that the sorbent is capable of scavenging 36.42 g/g of chloroform, 14.66 g/g of toluene, and 4.54 g/g of edible oils. More importantly, the foam composites are subjected to five adsorption-desorption cycles and the excellent reusability is demonstrated. The assynthesized PU foam composites can work as an efficient and durable oil-absorbing material for the separation of oils and organic solvents. These advantages make the MnO2 nanowires/PU foam composites an ideal candidate as an oil absorbents for oil spillage cleaning and oil/water separation.

The hydrophobic/oleophilic MnO2 nanowires were obtained by grafting the hydrophobic group on the surfaces of nanowires. In a typical procedure, 0.5 g of KH 570 and 3 g of MnO2 nanowires, 100 ml of distilled water were taken in a 250 ml three-necked round bottom flask with a mechanical stirrer for 2 h. Then, the mixture was then sealed and placed in the microwave reaction system (XH-100A, Beijing XiangHu Science and Technology Development Co., Ltd.) with a frequency of 2.45 GHz. The reaction system was rapidly heated to 85 _C at a power of 700 W, and maintained at 85 _C for 60 min with rotation and magnetic stirring. Finally, the microwave treated products were filtered, washed with distilled water, and then dried at 80 _C in air for 12 h before characterization.

京ICP备15050585号

京ICP备15050585号