- 路 Microwave

- 路 Atmospheric Pressure Microwave 路 Pressure Microwave 路 Parallel Microwave

- 路 Ultrasonic 路Low Temperature Ultrasound

- 路 Ultraviolet Light

- 路 Microwave Heating 路 Atmospheric Pressure Synthesis 路 Atmospheric Pressure Catalysis 路 Atmospheric Pressure Extraction

- 路 Sample Preparation 路 Microwave Digestion

- 路 Soil Digestion 路 High Pressure Synthesis

- 路 Solid Phase Synthesis

- 路 Organic Synthesis

- 路 Ionic Liquid Synthesis

- 路 Degradation Of Natural Organic Matter

- 路 Natural Product Extraction / Purification

河北祥鹄科学仪器有限公司

198 Antioxidation and a-glucosidase inhibitory activities of barley polysaccharides modified with sulfation

This paper, written by researchers from Yangzhou University and others, discusses Antioxidation and a-glucosidase inhibitory activities of barley polysaccharides modified with sulfation. The paper is published in an important journal < LWT - Food Science and Technology >. IF:3.129.

In recent years, the research work of microwave chemical instrument used in the synthesis of materials has become a hot direction of scientific research, which has been paid great attention to by many scholars!

Barley is a cereal to seek for higher value added. Its b-glucan has been paid much attention as a soluble dietary fiber. Barley polysaccharide (BP) of a cultivar for brewing was extracted by ultrasonic assistance and derived by using a relatively lower toxic esterifying agent-sulfamic acid to obtain sulfated barley polysaccharides (SBPs) with various degrees of substitution (DS). Comparisons were made amongst SBPs and BP in antioxidant abilities in vitro with total reducing power, scavenging effect on DPPH , hydroxyl radicals, superoxide anion radicals and lipid antioxidation and inhibition against a-glucosidase. The results showed that antioxidant activity of BP was significantly enhanced by sulfation modification. The activities increased with the concentration and DS. Kinetic analyses revealed that the inhibitory effects of SBPs and BP on a-glucosidase were reversible and SBPs exhibited a mixed type of inhibition while BP was a noncompetitively inhibitory process. The present work reflected that BP could be a potential raw material for the development of antiglycemic pharmaceuticals.

Fig.1/4↑

Fig.2/4↑

Fig.3/4↑

Fig.4/4↑

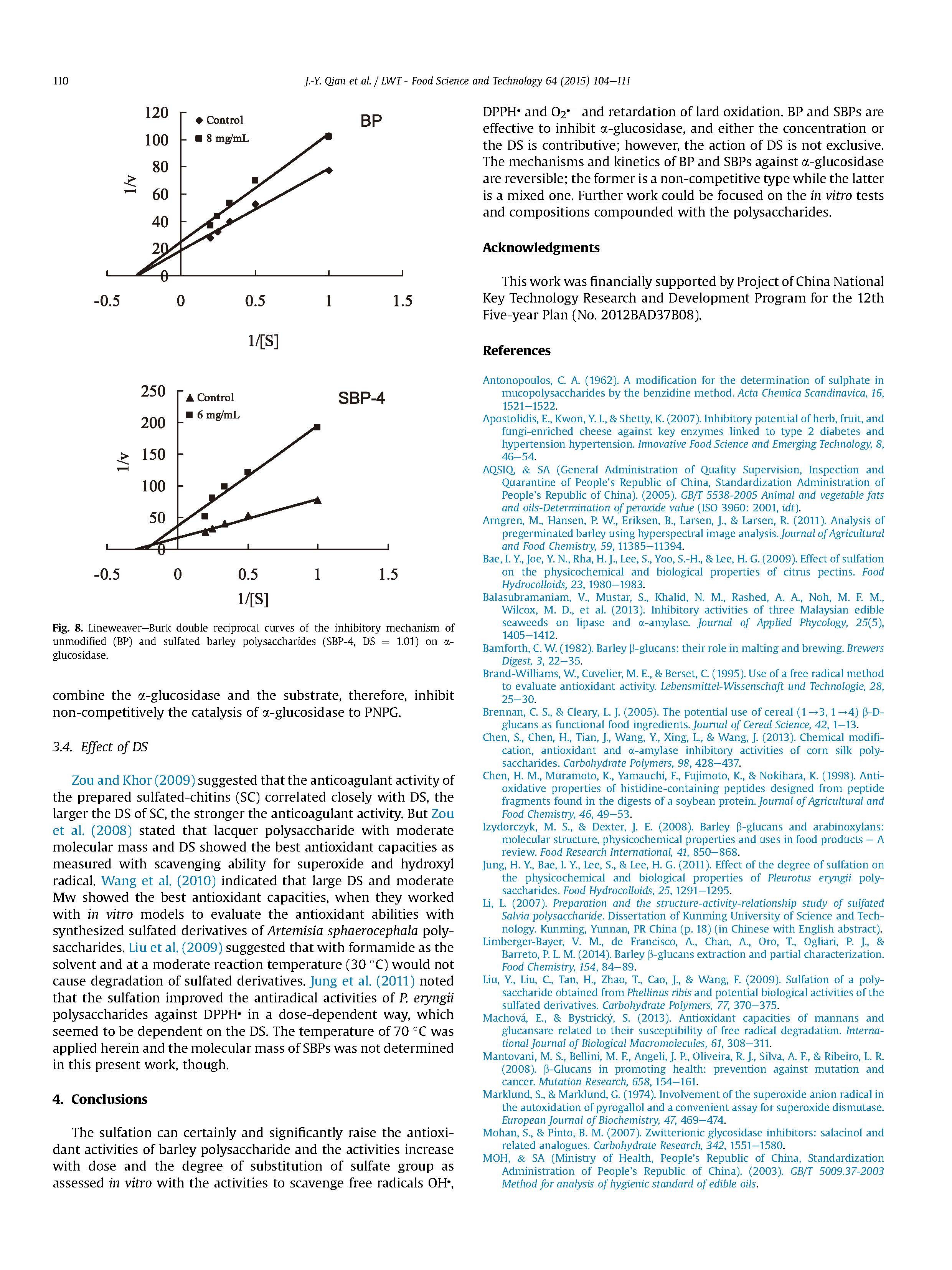

The sulfation can certainly and significantly raise the antioxidant activities of barley polysaccharide and the activities increase with dose and the degree of substitution of sulfate group as assessed in vitro with the activities to scavenge free radicals OH , DPPH and O2 and retardation of lard oxidation. BP and SBPs are effective to inhibit a-glucosidase, and either the concentration or the DS is contributive; however, the action of DS is not exclusive. The mechanisms and kinetics of BP and SBPs against a-glucosidase are reversible; the former is a non-competitive type while the latter is a mixed one. Further work could be focused on the in vitro tests and compositions compounded with the polysaccharides.

The procedure to extract and purify barley polysaccharide (BP) was optimized by response surface methodology in previous work. Barley kernels were cleaned and ground using a sample mill (GFSD- 70, Shanghai Jiading Cereals and Oils Inspection Instrument Company, China) before dry in an electro-heating driven-air dryer (DGX905 3B-2, Shanghai Fuma Experimental Equipment Co., Ltd., China) at 85 C for 1 h to inactivate endogenous enzymes, followed by removing lipids with petroleum ether (b. p. 60e90 C). After evaporating in a rotation distillator (RE-52D, Shanghai Yarong Bio- Chemical Instrument Factory, China) the solvent, 5 g of defatted barley flour was extracted with distilled water (1:25, m/v) at 75 C by the aid of ultrasonication (270 W) with a sonicator (XH-2008D PC Controlled Temperature Sonication Synthesizer and Extractor, Beijing Xiang Hu Science and Technology Development Co., LTD, China) for 8 min. The supernatant after centrifugation at 1500 g using a low-speed centrifuge (KDC-1044, Keda Innovation Co., Ltd., Zhongjia Branch, China) for 15 min was exerted to freezing and thawing process (Li, 2007) to remove protein and starch until neither protein nor starch was detected. The resulting polysaccharide solution was concentrated with a rotary distiller. Four volumes of 95% ethanol was added into the concentrate and standing overnight before centrifugation at 1500 g for 15 min. The pellet was finally dried using a freeze-dryer (Alphal-2LDPlus, Christ, Germany, temperature 55 C) to obtain BP.

京ICP备15050585号

京ICP备15050585号